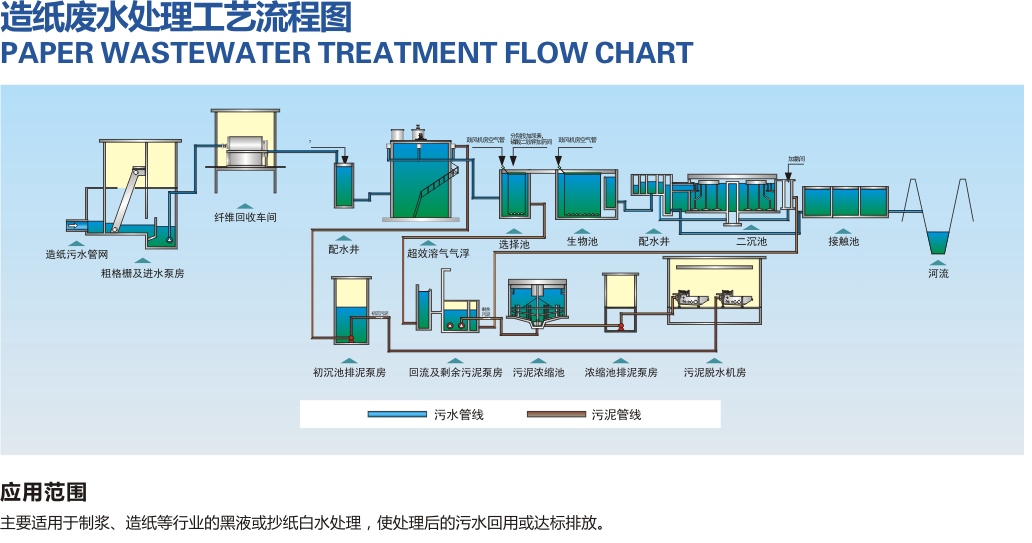

Papermaking

Papermaking wastewater treatment process:

The waste water diversion canal flows through the coarse grid filter material, into the sump, pump to microstrainer recycled fiber flows into the regulation pool, sedimentation of mud and sand debris, then pump to improve flotation machine, adding a number of drug pump before entering the coagulation reaction, coagulation reaction when the waste water "electric demulsification" neutralization adsorption, the formation of fine alum, adding two medicine machine, flocculation rely on two medicine, on the net sweeping, alum alum into tidbits group in the reaction cylinder intensive aeration bubbles floating under the effect of floc water and solid-liquid phase separation in water enrichment, in promoting the role of the water under the mud scraper movement along the surface, the suspension into the sludge discharge pipe, by gravity will be discharged to the collector scum into the sludge drying tank natural drying or drying, filter press, filter press sludge Sinotrans landfill or mix When the coal is burnt, the clear water is discharged from the lower adjusting plate, and the water enters the biochemical treatment module through the pipeline. The process is simple and efficient use of activated sludge and by chemical precipitation to improve the removal rate of suspended activated sludge, Fanai impact load capacity, high organic removal rate, the treatment effect is stable and reliable. The aeration system is developed by our company, which has the advantages of aeration effect, land occupation, noise, power consumption and operation and maintenance. According to the above mentioned, the mixed wastewater can be completely discharged after treatment.