Sludge Dewatering

DU series continuous belt vacuum filter

Date:2017-03-21 15:32:02 From: Browse times:

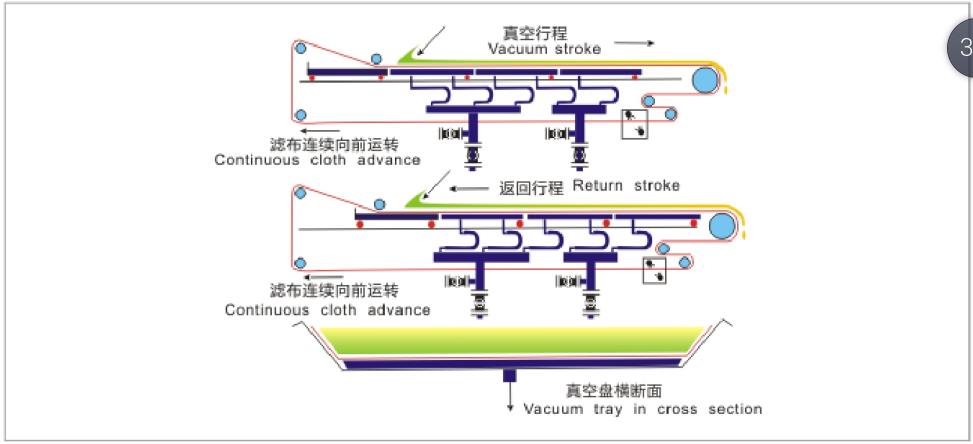

DU series continuous vacuum belt machine is in vacuum as the impetus for the realization of solid-liquid separation equipment in the structure, the filtering section arranged along the horizontal direction, can complete the filtration, washing, dry cloth regeneration, continuous operation. The equipment has the advantages of high filtration efficiency, large production capacity, good washing effect, low moisture, flexible operation, low maintenance cost and so on. The utility model can be widely used in the separation of solid and liquid in the fields of metallurgy, mining, chemical industry, papermaking, food, pharmacy, environmental protection, etc., and has good application in the aspects of the gypsum dewatering of flue gas desulfurization (FGD).

The device uses a fixed vacuum box, tape slide in the vacuum box, type vacuum box and a sealing tape motion, it can automatically complete the filter, the filter cake washing and discharging slag, cloth regeneration process, and the mother liquor and the filter cake washing liquid can be segmented collection, has high filtration efficiency and large capacity, good washing efficiency, low moisture of filter cake, simple operation and easy maintenance. The plane passed through our years of improvement, functional properties and quality of products have reached the international advanced level, has been widely used in metallurgy, mining, chemical, papermaking, pharmaceutical, food, power plant, wet flue gas desulfurization of coal chemical industry and environmental protection industries.

An annular rubber discharging belt, high tensile strength, long service life, a vacuum box and a friction ring belt belt, and sealed and lubricated with water, can maintain a high degree of vacuum, and to reduce the friction of the rubber band.

The core of the adhesive tape is sealed with a supporting rod or a water film support, thereby reducing the running resistance and prolonging the service life of the adhesive tape.

The vacuum drainage adopts the free fall type (high level drainage), automatic drainage (zero discharge) and other methods to meet the requirements of various working conditions.

It uses a modular design structure, flexible assembly, convenient transportation and convenient installation.

The control system uses the DCS technology, can realize the field and remote automatic control.

Working principle:

| Filter width(m) | 1.3 | 1.8 | 2.0 | 2.5 | 3.2 | 4.0 | 4.5 | ||||||||

| Filter length(m) | N | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T | Filtration area/㎡ | weight/T |

| 8 | 3 | 10.4 | 8.3 | 14.4 | 12.7 | 16 | 14.2 | 20 | 20.0 | 25.6 | 26.3 | ||||

| 10 | 4 | 13.0 | 9.0 | 18.0 | 13.7 | 20 | 15.4 | 25 | 22.0 | 32.0 | 28.5 | ||||

| 12 | 5 | 15.6 | 10.5 | 21.6 | 15.3 | 24 | 17.2 | 30 | 25.3 | 38.4 | 32.9 | 40 | 48.0 | 54 | 55.0 |

| 14 | 6 | 18.2 | 11.5 | 25.2 | 16.6 | 28 | 18.7 | 35 | 27.4 | 45.0 | 35.3 | 56 | 51.0 | 63 | 57.9 |

| 16 | 7 | 20.8 | 12.5 | 28.8 | 17.9 | 32 | 20.2 | 40 | 29.5 | 51.2 | 37.7 | 64 | 53.6 | 72 | 60.8 |

| 18 | 8 | 23.4 | 13.5 | 32.4 | 19.2 | 36 | 21.7 | 45 | 31.6 | 58.0 | 40.1 | 72 | 56.2 | 81 | 63.7 |

| 20 | 9 | 26.0 | 14.5 | 36.0 | 20.5 | 40 | 28.0 | 50 | 38.6 | 64.0 | 42.5 | 80 | 58.8 | 90 | 72.0 |

| 22 | 10 | 39.6 | 21.8 | 44 | 30.0 | 55 | 40.9 | 70.4 | 51.0 | 88 | 66.6 | 99 | 75.2 | ||

| 24 | 11 | 48 | 32.0 | 60 | 43.2 | 77.0 | 53.5 | 96 | 69.4 | 108 | 78.4 | ||||

| 26 | 12 | 65 | 45.5 | 83.2 | 56.0 | 104 | 72.2 | 117 | 81.6 | ||||||

| 28 | 13 | 89.6 | 58.5 | 112 | 75.0 | 126 | 84.8 | ||||||||

| 30 | 14 | 96.0 | 61.0 | 120 | 77.8 | 135 | 88.0 | ||||||||

Previous:SF sand water separator

Next: